Discolouration of Liners

Staining

Liners do not stain by themselves. There is always an outside agent causing thee staining. Probably the most common form of liner staining is that caused by bacteria or micro organisms growing behind the liner. The gases given off by these bacteria/micro organisms (principally hydrogen sulphide and methane), permeate through the membrane and react with dissolved metals in the pool water (copper, iron) causing staining on the visible side of the liner.

Fortunately, this type of staining is not permanent. If the cause of the staining is removed, then the stains will gradually fade and eventually disappear. There are two ways of tackling the problem. One is to destroy the bacteria/micro organisms behind the liner with chlorine which means emptying or part emptying the pool in order to gain access to the areas in question. This is not always desirable. The other method is to remove the dissolved metals from the pool water so the gases permeating through the liner have nothing with which to react. This can be achieved by the Alkorplus 81059.

Fortunately, this type of staining is not permanent. If the cause of the staining is removed, then the stains will gradually fade and eventually disappear. There are two ways of tackling the problem. One is to destroy the bacteria/micro organisms behind the liner with chlorine which means emptying or part emptying the pool in order to gain access to the areas in question. This is not always desirable. The other method is to remove the dissolved metals from the pool water so the gases permeating through the liner have nothing with which to react. This can be achieved by the Alkorplus 81059.

Anti Stain Alkorplus 81059

Alkorplus 81059 is a patented anti stain product that has been developed as a water treatment that offers a safe and simple method of reducing the presence of dissolved metals in swimming pool water.

The anti stain Alkorplus 81059 is a mineral dispersion with a 30% concentration. It is non toxic and is not an irritant. It should not be mixed with acids under any circumstances as, in its concentrated form; it will produce an inflammable and irritating gas. Metal or metal salts from ions when dissolved in water. Alkorplus 81059 neutralises various metal ions such as copper, lead, tin, cadmium and silver.

Alkorplus 81059 consists of small insoluble granules which are poured directly in to the skimmer, forming an active layer within the filter. Dissolved metals are absorbed by the product and are subsequently removed from the water, together with the product, when cleaning or back flushing the filter. A new dose of the product, when cleaning or back flushing the filter. A new dose of the product must be added ever time the filter is backwashed. Alkorplus 81059 is NOT compatible with sanitising treatments that are based on the presence of dissolved metals in the pool water such as copper sulphate and electrophysical systems.

Product dosage is determined by the amount of dissolved metals in the pool water. Sources are from corrosion inside the heat exchanger, impurities in other water treatment products or replacement of all or part of the pool water. Replacement tap water contains u pto 0.2 ppm of copper.

The prescribed dose is:-

a) 40ml (cap volume) of the product per 50 cubic metres of water per week during the swimming season.

b) 80ml of the product per 50 cubic metres of water at the beginning of the season or after filling or topping up the pool.

As the product itself is removed when the filter is cleaned, it is important that Alkorplus 81059 is added after backwashing. T be totally effective, the entire volume of the pool water must be circulated through the filter regularly.

Outside of the swimming season, the anti stain treatment with Alkorplus 81059 is not necessary as the risk of newly dissolved metals appearing is minimal as long as other water treatment products do not contain impurities (“see note below”). It is strongly advised that chlorine tablets should not be placed in the skimmer outside of the swimming season or when the circulation pump is not operating as this would encourage concentrations of chlorine which will cause corrosion to the metal parts of the pump, heater and filtration equipment. This would add to the presence of dissolved metals in the pool water which might then cause staining of the membrane if the use of Alkorplus 81059 has been discontinued.

The presence of metal impurities in water treatment products may be easily tested as follows:-

Pour 5ml of of the water into a glass container (if the product to be tested is in solid form, dissolve 1gm into 5ml of water). Add three drops of the anti stain Alkorplus 81059, mix the solution for about 15 seconds and wait 10 minutes for a reaction. If heavy metals are present, the white Alkorplus 81059 will turn grey.

This test must be carried out in open air.

If the product being tested is very acidic )e.g. anti-lime products and certain scum line cleaners) an unpleasant smell ma be released.

Note: Acid base cleaners are not recommended for cleaning around the water line of PVC pool liners.

Staining Caused by Tape

It is important to make sure that any tapes used for joining underlay or for any other use where they are likely to come into contact with the liner, are compatible with PVC liner material. Some tapes, particularly those commonly known as “duck tape” or “gaffer tape” can stain or distort the liner.

It is important to make sure that any tapes used for joining underlay or for any other use where they are likely to come into contact with the liner, are compatible with PVC liner material. Some tapes, particularly those commonly known as “duck tape” or “gaffer tape” can stain or distort the liner.

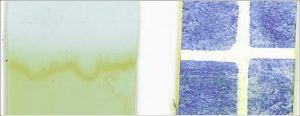

Interestingly, tape can also sometimes act as a barrier to staining. In the picture the stains are broken up by straight lines of tape under the liner which are preventing or at least delaying the process of the hydrogen sulphide gas permeating the liner.

Similarly the welds of the liner can present a barrier to staining as they are essentially a double thickness of material. Another side to this phenomenon can be seen at the end of the process when the staining is receding – the welded areas retain the stain longer and remain the last sections to be free of staining.

Bleaching/Fading

The main cause of liner fading above the water line is UV light. Liner material contains additives which will resist UV degradation but they can only do so much. Slight fading will start to occur from day one as can be noticed if a patch of virgin material is applied six months after the liner was installed. After the first three or four years, the rate of fading can increase noticeably.

The main cause of liner fading above the water line is UV light. Liner material contains additives which will resist UV degradation but they can only do so much. Slight fading will start to occur from day one as can be noticed if a patch of virgin material is applied six months after the liner was installed. After the first three or four years, the rate of fading can increase noticeably.

Liner material will take on a slightly paler appearance when it absorbs moisture below the water level. This is noticeable when the water level drops suddenly. The full colour will return when the material dries out. Keeping the pool covered when not in use and maintaining correct water chemistry will help to extend the appearance and life of the liner.

A more dramatic form of colour fading is that caused by chemical attack (bleaching). Common culprits are chlorine (in its liquid form especially), acid and hydrogen peroxide. It is vital that any chemicals added to the pool be thoroughly mixed with water in a bucket and then dispersed evenly around the pool.

Whilst the print on patterned liners is protected by an acrylic lacquer, it is possible to mistreat the liner in such a way as to remove some of the lacquer and print, leaving the base material visible. The most common causes of this are abrasive tile band cleaners, incorrect footwear during liner fitting, sharp edges on telescopic poles, brushes, etc., and automatic pool cleaners if they have become trapped in one position (usually a corner) for too long. A rough screed under the liner can result in print abrasion or even holes. Never leave automatic pool cleaners unattended for long periods.

Surface deposits

Perhaps the most common forms are calcium deposits (usually caused by incorrect pH balance) and body/sun tan oils. A reaction between modern sun creams and copper in the pool water can cause yellow staining on the liner material above the water line. Apart from the obvious discolouration to the liner, calcium deposits may well be an indication of more serious damage being done to pumps and heaters etc. Other surface deposits include wind borne chemicals from adjacent farms or aviation fuel and occasionally sticky deposits from some biguanide sanitizers.

In most cases, staining of the water line is a combination of:

- Photo-oxidation of the waterproofing membrane: the sun, water and chemicals can change the surface of the plastic material in an irreversible way.

- Atmospheric pollution: dust, smoke, residues of the combustion of fuels, will float on the water surface and will be driven by the wind towards one side of the swimming pool, where they will deposit onto the waterproofing membrane.

In the UK, the dominant wind direction is from the southwest. Atmospheric pollution will be deposited on the northeast walls. These are also the walls that receive the highest quantity of solar energy. These will typically be the sides where staining of the water line will be worst, as the effects reinforce each other. Of course, the presence of buildings and trees will also have an influence. Regular cleaning of the water line is the best way to prevent early degradation and are easier to clean. Propriety products specifically designed for cleaning PVC liners should be used to remove staining. Under no circumstances should solvents or abrasives be used on Aquaflex liners as they will remove the protective lacquer and any print.

Yellow staining

In recent years yellow staining of the water line has become an increasing problem. These stains do not correspond in any way with the usual pollution of the water line, which is generally grey/black/brown colour, and which is not too difficult to remove if cleaning is carried out on a regular basis. Grey staining is generally found on the down wind side of the pool. The yellow stains have a very distinctive colour; they appear in less than two days and they are very difficult to clean. Several pool owners have stated that the stains appeared after people using sun cream had made use of the pool. Laboratory tests have shown that the most probable cause of the staining is a reaction between sun cream and copper.

Lacquered membranes are less easily stained than unlacquered products, but there is still a possibility of some staining.

Liners that have come in contact with sun cream and chlorinated water.

Liners that have come in contact with sun cream and chlorinated water that contains copper.

The yellow stains dissolve in highly chlorinated water. So, theoretically it is possible to remove the stains by raising the water level above the stains and shock chlorinating the swimming pool water. In practice the stains dissolve rather slowly, so it can take several weeks before the stains have disappeared, and the high chlorine level could also attack the swimming pool membrane. The yellow stains also dissolve in strong solvents, such as ethyl acetate. This solvent can only be used to remove the yellow staining on plain lacquered liners. Ethyl acetate cannot be used on printed products as this solvent will remove the lacquer and print. A better method is to avoid staining by not using copper-based water treatment products.

Lacquered membranes are less easily stained than unlacquered products, but there is still a possibility of some staining. Nowadays, in many European countries, copper sulphate is rarely used. As an algicide, it has largely been replaced by quarternary ammonium compounds, which have the added advantage of not colouring the swimmer’s hair. The major manufacturers of swimming pool chemicals offer products without copper sulphate specifically for liner pools.

Liner pools have no rough surfaces, such as the grouted joints in ceramic pools; therefore a liner pool does not really need algicide: it is perfectly possible to maintain good water quality with only the use of chlorine tablets.

WARNING: If the pool has an automatic salt chlorination system without the correct dosing control, there is a great danger that the pool water will be over chlorinated. This will result in colour/pattern loss of the pool liner. PLEASE SEEK SPECIFIC ADVISE FROM YOUR SALT CHLORINATOR SUPPLIER.